P.B.-M. SCANBET sp. z o.o.

For 27 years, we have been manufacturing precast reinforced concrete elements upon individual request. The experienced engineer team of SCANBET will help you implement your design regardless of scale or complexity. Everything will be completed on time, including the delivery to a location of your choosing.

Manufacturer

of precast reinforced

concrete elements

PRZEDSIĘBIORSTWO BUDOWLANO-MONTAŻOWE “SCANBET” spółka z ograniczoną odpowiedzialnością was formed in 1996. Since the beginning of our operations, we have been making precast reinforced concrete elements for residential and industrial buildings and engineering structures. We do not make any standard items. Our precast items are made and delivered upon request, tailored to the specific needs of construction projects.

Our areas of expertise include the production of reinforced concrete balconies, staircases, solid and composite walls, lift shafts and structural members such as columns and beams. Items exposed to variable weather conditions, e.g., balcony slabs, are made of concrete with higher frost resistance, and thin-wall members or complex elements are made of SCC concrete. We also make 3D elements such as tanks. We make our products from concrete of classes ranging from C30/37 to C50/60, and we can currently make more than 1500 precast elements per month.

Our history

2015

- Dynamic growth of export into Germany

- Sales volume of finished products exceeds PLN 40 million

2014

- Sales volume of finished products exceeds PLN 30 million

2007

- Construction of a production building, presently known as building “A”

2005

- Conversion of the old boiler house building into an office and welfare building

Solutions

for real estate developers

and the industrial sector

We work together with engineering companies that design structures from precast items. We offer a robust solution for real estate developers and the industrial sector.

Production

We make high-quality precast concrete items upon individual request.

Transport

We offer international transport services and special transport of precast items.

Partnership

We believe in partner-like relations with our clients. Transparent and professional.

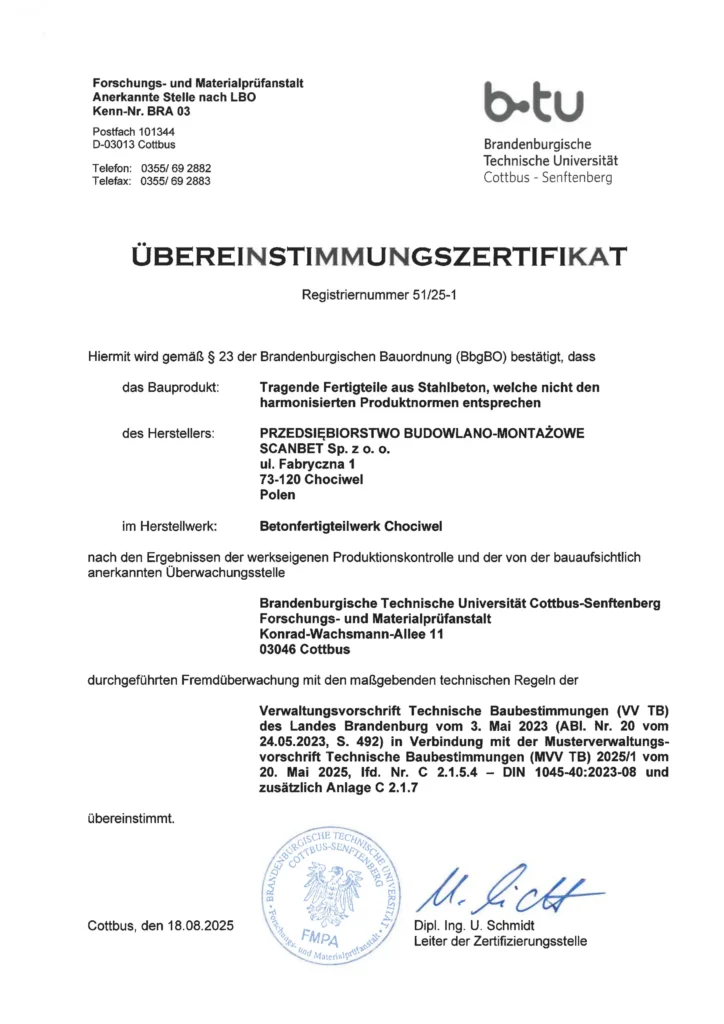

Quality

We have our own laboratory. Our precast items are scrupulously tested.

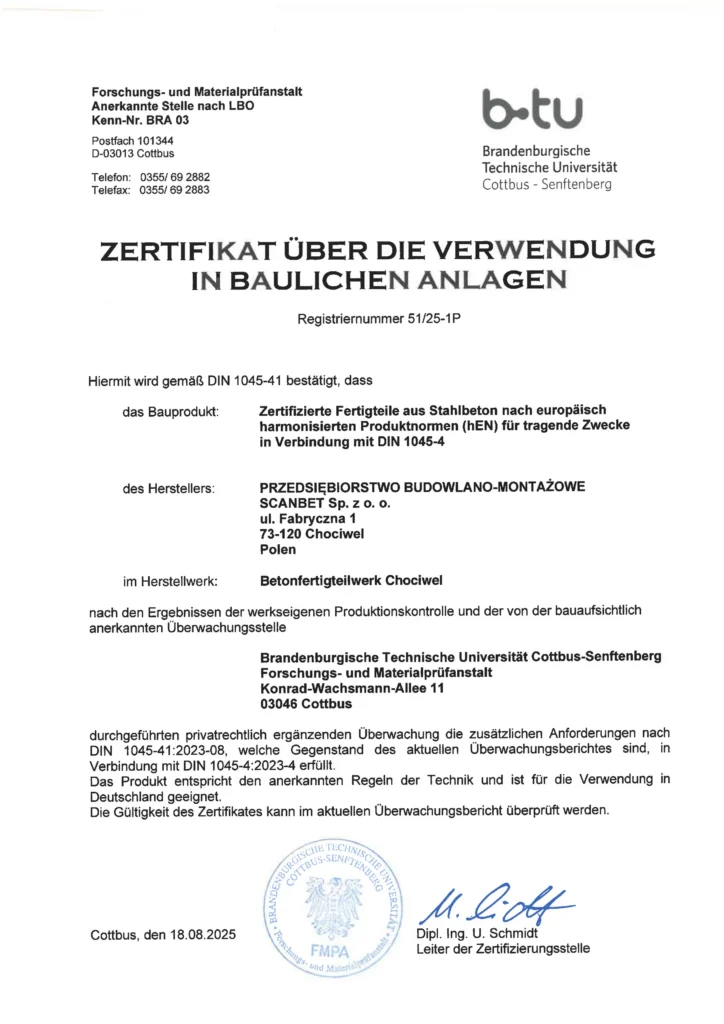

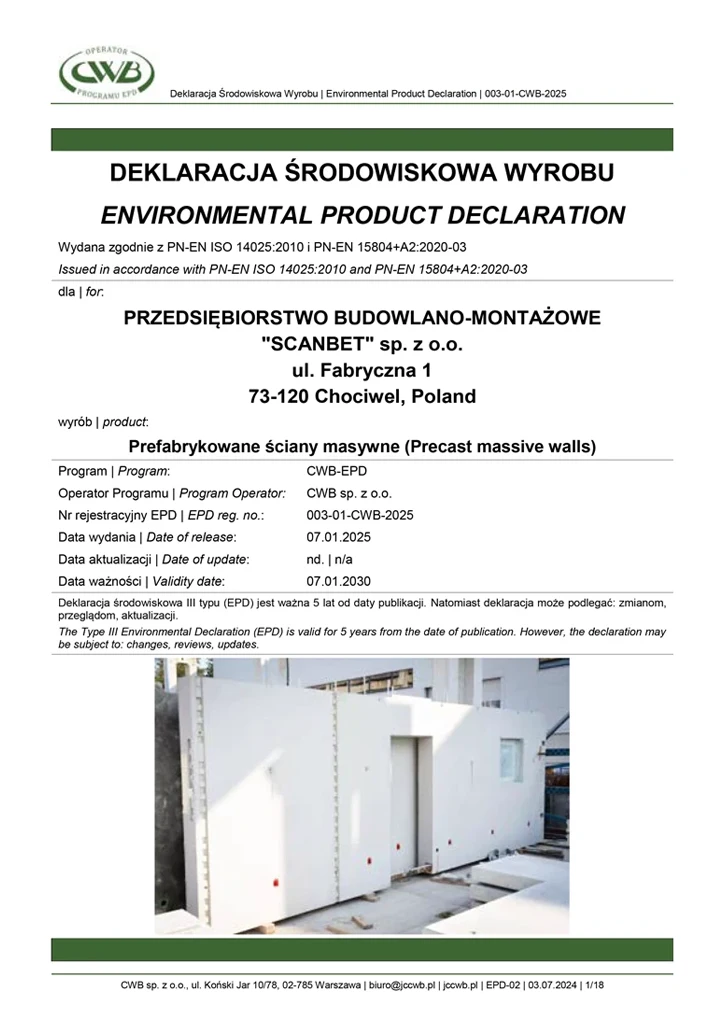

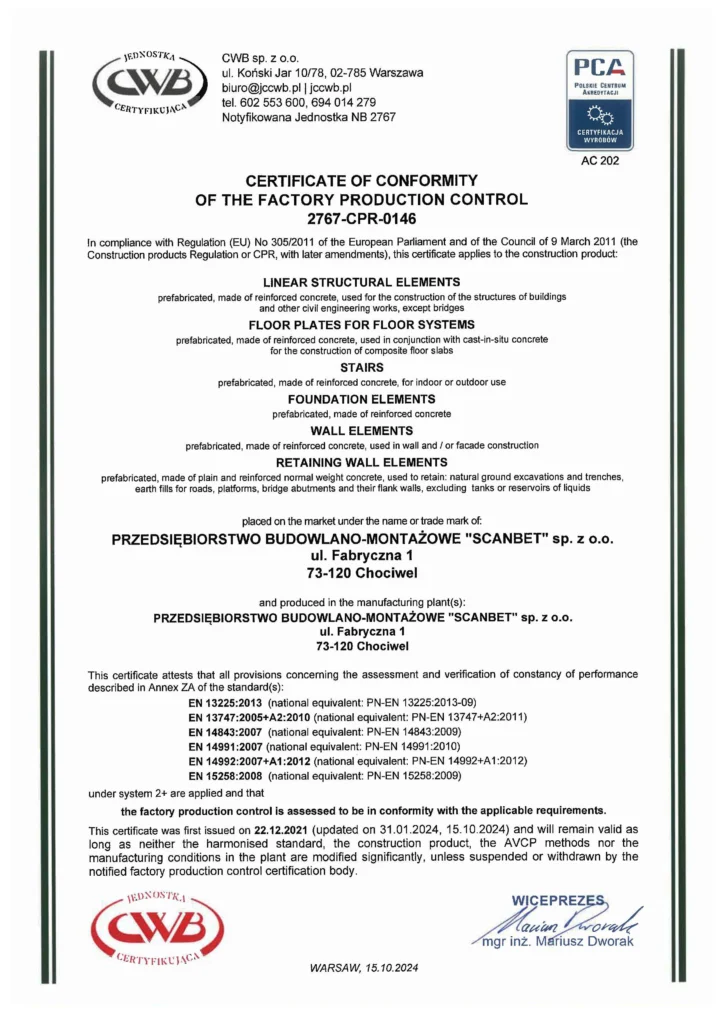

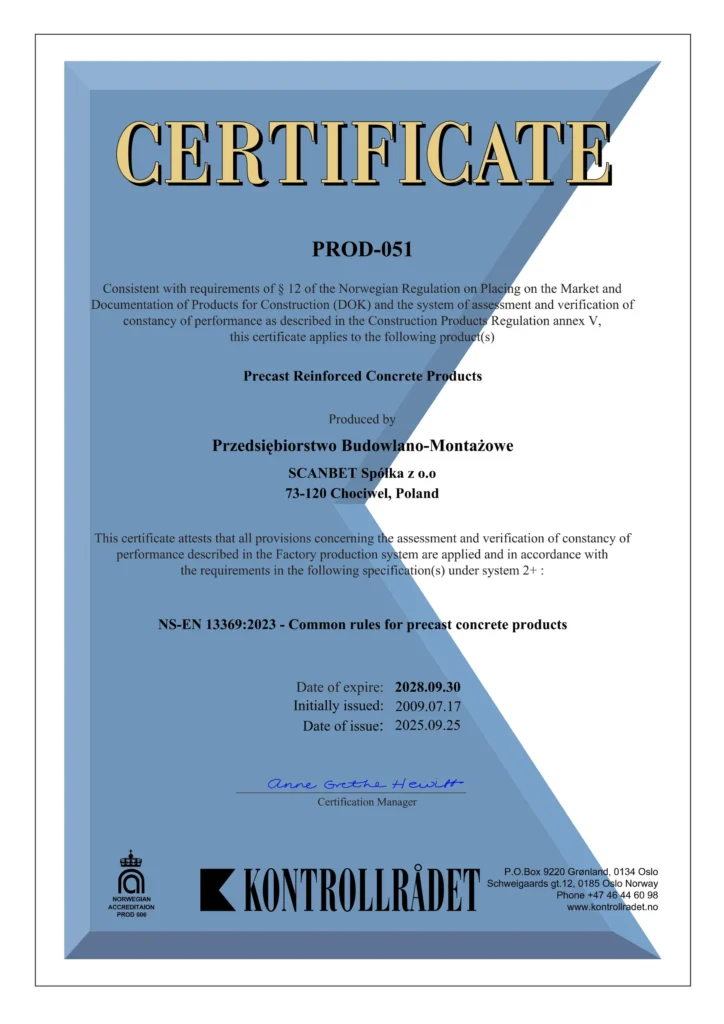

Certified and standardised

production processes

at every stage